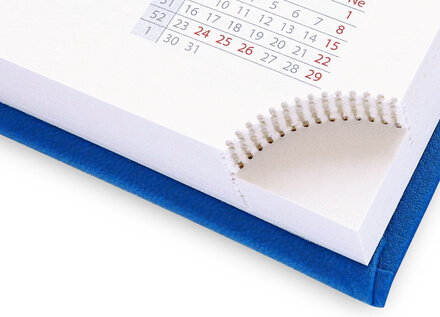

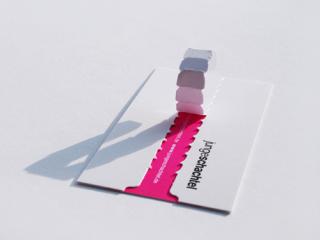

Perforation is a process used in the printing industry to allow easy separation of two sections of the material, such as allowing paper to be torn easily along the line. Perforation is mostly used for loose-leaf coupons, calendars, postage stamps, leaflets and notepads. It can be used instead of creasing: perforation makes extra-thick materials to be folded in a straight manner with no paper cracks.

No printed product with to-be-torn elements can do without perforation.

Types of perforation:

- impact perforation;

- micro-perforation;

- segment rotary perforation;

- tear-off corners perforation and grooving.

Perforation line may be perfectly straight, round, segmental or have curves – it’s up to you!

Perforation technology

Ulmapress applies perforation, using special equipment and specific perforating rules or replaceable disk knives.

Folding machines are often used with disk knives attached in order to perforate material that moves along the machine table.

Pressing equipment is used to create combined perforation lines whose direction depends on location of perforating rules.

Even the smallest details are of great importance in perforation process: holes must be exactly perforated, edges must be smooth, while perforated elements should be properly removed from the product. Our specialists carefully treat every detail, completing your order quickly and qualitatively and taking into account all your wishes.