Folding is one of the post-printing processes.

This operation is intended to fold sheet in a straight manner. Folding is mostly used for brochures, flyers, postcards, magazines and books. Folding can be manual and machine-assisted.

Folding process has a number of requirements:

- page sequence must be observed;

- folds must be perfect; vno wrinkles are allowed;

- no blurred impressions are allowed;

- adequate signature construction should be observed;

Number of folds depends on product’s size and features. In case of a paper thicker than 170 gsm, folding is preceded by creasing operation.

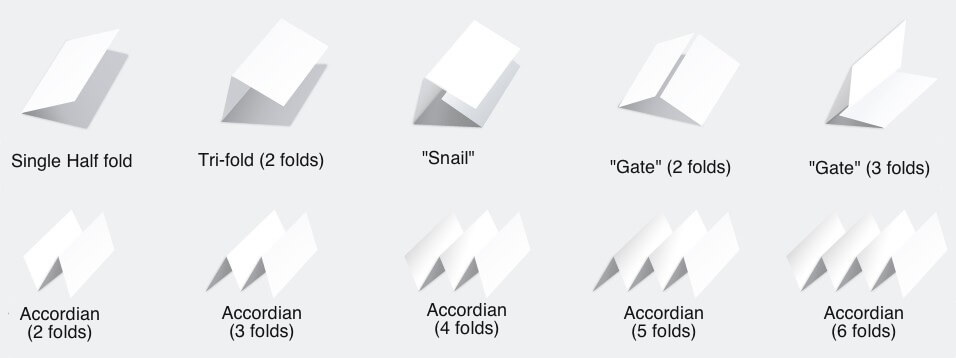

The most common folding types are:

- each subsequent fold is perpendicular to the previous one;

- each subsequent fold is parallel to the previous one;

- printed sheets get folded perpendicularly and in-parallel.

In the printing industry meaning of the word "creasing" should not be confused with folding. These processes are quite different, and are performed in a certain sequence, using different equipment.

As a rule, folding is preceded by creasing. Creasing facilitates the process of folding. Folding is used to form a signature or other product from sheets that are already printed.

Folding operation is used to make some consecutive folds. Using this method, you can easily form a booklet, book or magazine from several signatures. Folding process depends on paper thickness and weight, its humidity and grain direction with regard to fold. Folding method is also an important thing.

Creasing is the process of forming grooves of certain width along the folding line on impression, when paper thicker than 170 gsm or cardboard is in use. Creasing significantly facilitates the following folding process. Creasing is widely used in the manufacture of postcards, folders, covers, etc. Creasing can also be manual and machine-assisted. The best creasing method depends on a number of factors.

Important: during the course of automated creasing a paper crack may occur if the crease line is located perpendicularly to the long-grain of paper. In this case, manual creasing is to be done, as it guarantees more qualitative performance. It is also used after UV-varnishing and lamination. But keep in mind: manual creasing is much more labour-consuming and expensive method than automated one and is not suitable for large runs.